of historic data

monitored

of model training

Challenge

EWT wind turbines are stationed from the north pole to the desert, in urban areas and at sea. The difficult accessibility and extreme weather conditions turn maintenance of turbines into a challenging job. Therefore it is of crucial importance to foresee a defect. The growing complexity of the turbines makes it harder for the EWT's engineers to interpret data. Based on this growing need for machine assistance, EWT and Bit joined forces to experiment with Machine Learning as a predictive maintenance tool.

Hypothesis

Wind turbines consist of moving and fixed parts. These parts meet inside a bearing, causing friction and heat that produces energy. Lubricating oil is used to prevent the temperature within the bearing from becoming too high. An abnormality in this bearing temperature is a good indicator for deviating behavior. This was the key hypothesis for our jumpstart.

Research and prototyping

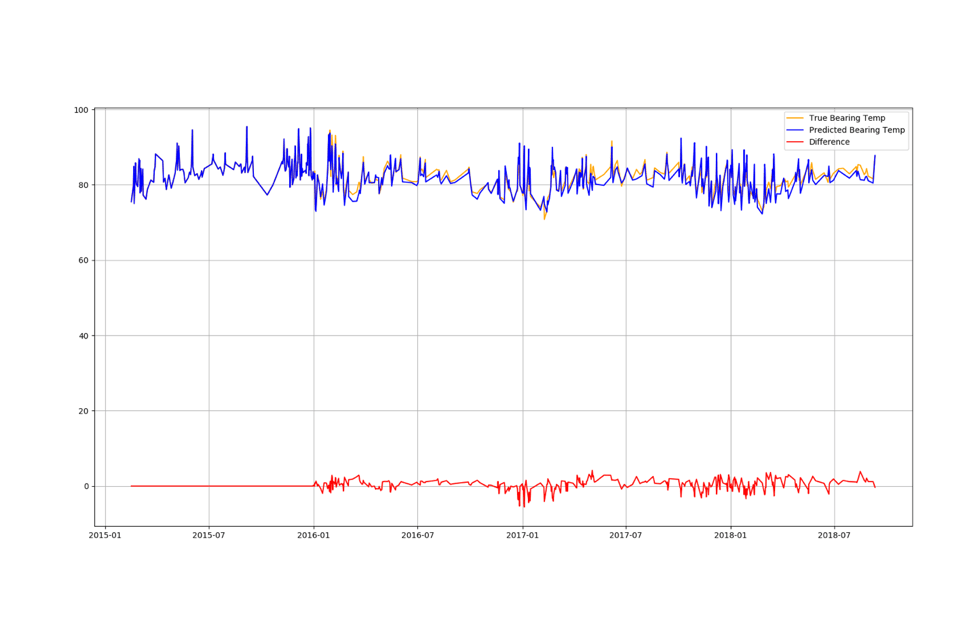

Using bearing temperature as the single indicator for failure would only work under specific turbine and weather conditions like cold, heat and wind. Therefore technically experienced engineers and data driven experts trained a model including a variety of features like outside temperature and turbine spinning speed. Within weeks the model was able to accurately reproduce the historic data, indicating the model would be able to predict future failures. During a prototype demo, a recently noticed aberration in one of the turbines came up. The perfect moment to check if our model had noticed too. And guess what? We finalized the project by implementing a control panel in the control room of the EWT, assisting the engineers with machine based predictive maintenance.

Looking to find your opportunities through emerging tech?

marco@wearebit.com+312 073 707 63

Call Marco